MONSEC® enables remote monitoring of concrete setting in construction projects and provides accurate, real-time information on concrete strength and maturity during the setting process.

The MONSEC® system uses next-generation wireless sensors for the automatic recording of key parameters inside the formwork, processes the data in the cloud and provides you with key parameters for decision-making in the management of concrete curing and optimization of concrete.

Integrated and automated system

Accurate information in real time

All your formwork in one tool

Information in the cloud accessible 24/7

Programmable measuring time for each sensor

Alarms via SMS

Optimize deadlines and costs

Quick and easy to implement

Automate the control of your formwork

The MONSEC® system uses ultra-low consumption wireless sensors distributed throughout the formwork. After the concrete has been poured, the sensors measure the temperature and humidity at programmed intervals, providing constant information about the conditions inside the concrete.

The MONSEC® web application allows access to this information in real time, from anywhere.

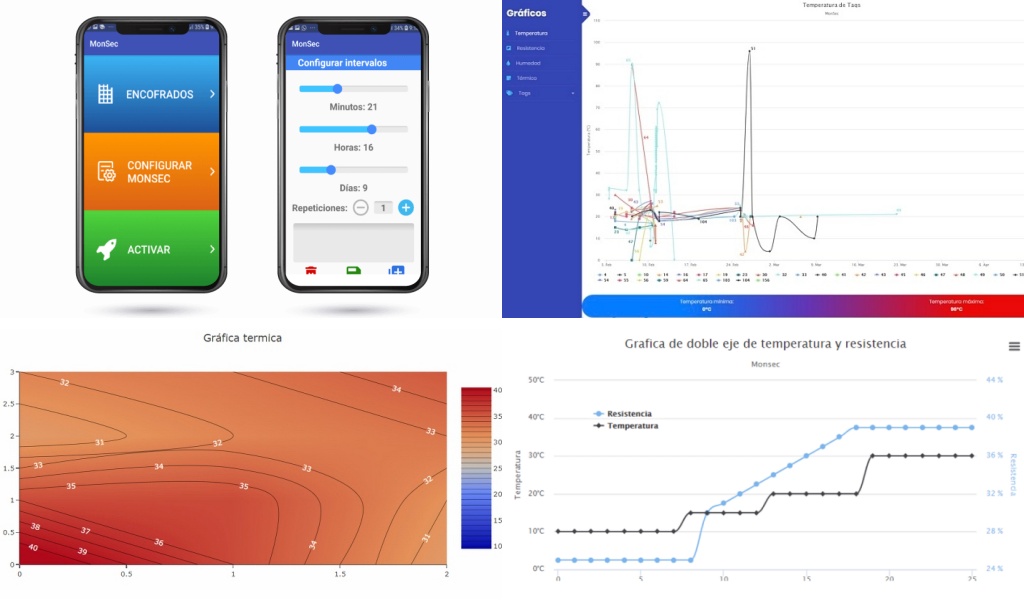

Configuration in minutes with the mobile app

The introduction and configuration of the formwork in the system is done with the MONSEC® mobile application. This application allows to generate an unlimited number of forms, plan the distribution of the sensors in each project and parameterize the measurement intervals of the sensors independently, as well as program automatic alarms in case of deviation from the expected values.

Presentation of key parameters in real time

The intelligent MONSEC® algorithms perform a precise calculation of the instantaneous resistance of concrete Rc (MPa) from the temperature and relative humidity records made by the sensors. Through the MONSEC® web application, you can track key parameters, view evolution charts and generate reports at any time during the process.

Real-time temperature graphs.

Relative humidity graphs in real time.

Calculation of compressive strength.

Thermal diagram in formwork with multiple sensors.

Your ally in decision making

With MONSEC® you can manage all your projects on a single platform, save unnecessary waiting time for stripping and reduce the risk of non-conformity in compression tests using specimens.

The automation of data collection and processing saves time and human resources, while remote access to information makes it possible to streamline processes and decision-making on formwork interventions.

The Monsec sensor family

Monsec

Wireless sensors of ultra-low consumption and high coverage, which measure the temperature and humidity of the concrete during the setting process.

They work with a battery with a lifespan of approximately 90 days and take readings at pre-defined intervals. Once installed inside the formwork, they measure key parameters and communicate by UHF radio signal with the Monsec station, which sends the data to the cloud.

The Monsec sensors help to choose the optimal moment for removing the formwork, saving any unnecessary waiting time.

Monsec cable

Ultra-low consumption wireless sensors that measure the temperature and humidity of the concrete through a measuring element connected by cable, with different lengths (up to 15m) to the Monsec sensor, thus being able to reach greater depths according to the needs of the constructive elements.

There are options to run on batteries or connected to the mains. The sensors communicate directly with the Monsec station by UHF radio signal and it sends the measurements to the cloud where they are processed and visualized in the Monsec App.

Monsec thermocouple

Monsec thermocouple makes it possible to obtain high-precision data on the temperature of the concrete at a large number of points inside the structure, with models available with 4 or 8 ports.

The measuring elements are connected by cable to the Monsec sensor which transmits the measurements using a WiFi connection, data SIM or both.

Monsec thermocouple is powered by a battery with an approximate lifespan of 90 days.

Monsec Smart

Ultra-low consumption wireless sensors that measure the temperature, humidity and strength of the concrete.

Using algorithms developed with Smart Engineering (UPC), Monsec Smart performs a precise calculation of concrete resistance (Rc) according to ASTM C1074 regulations.

The automated obtaining of accurate data in real time facilitates decision-making, providing security and optimization in the evolution of the works.

It communicates with the Monsec station through a UHF radio connection and works with a battery with a life time of approximately 90 days.

Monsec Cable Smart

Ultra-low consumption wireless sensors that measure the temperature, humidity and strength of the concrete.

With algorithms developed with Smart Engineering (UPC), Monsec Fil Smart performs a precise calculation of concrete resistance (Rc) according to ASTM C1074 regulations. They take measurements of key parameters through a measuring element connected by cable, with different lengths (up to 15m) to the Monsec sensor, allowing to reach greater depths according to the needs of the construction elements.

There are options to run on batteries or connected to the mains. The sensors communicate directly with the Monsec station by UHF radio signal and it sends the measurements to the cloud where they are processed and visualized in the Monsec App.

Monsec Thermocouple Smart

It allows obtaining high-precision measurements on the temperature and resistance of the concrete at various points inside the structure, with models available with 4 or 8 ports.

Using algorithms developed with Smart Engineering (UPC), Monsec Termocouple Smart performs a precise calculation of concrete resistance (Rc) according to ASTM C1074 regulations.

The Monsec sensor is connected by cable to the measuring elements and transmits the data via WiFi connection, data SIM or both.

It is powered by a battery with an approximate life of 90 days.

Monsec EXT

Ultra-low consumption wireless sensors that measure the temperature, humidity and strength of the concrete.

Using algorithms developed with Smart Engineering (UPC), Monsec Smart performs a precise calculation of concrete resistance (Rc) according to ASTM C1074 regulations.

The automated obtaining of accurate data in real time facilitates decision-making, providing security and optimization in the evolution of the works.

It communicates with the Monsec station through a UHF radio connection and works with a battery with a life time of approximately 90 days.

Monsec Humidity

Humidity measures with great precision the temperature and humidity inside different materials, such as concrete in the curing process, or inside walls or different types of walls.

It is very useful in the area of cultural heritage conservation.

The measuring elements of the sensor are inserted inside the material and are connected by cable to the Humidity sensor.

The sensor is connected to the electrical network and sends the measurements to the station via a WiFi connection.

Monsec HRC Sensor

HRC Sensor allows the on-site measurement of humidity and temperature.

The sensors are located at key points to know the relative humidity conditions.

They are connected to a power source and communicate directly with the Monsec station via WiFi connection.

Monsec SUP

Wireless sensors that accurately measure temperature and humidity on a surface (wall, floor…).

The sensors are installed on the surface of the wall and communicate directly with the Monsec station, which transmits the measurements to the cloud.

They work with a power source, although they can also have a built-in battery and are very useful for detecting the presence of moisture in building elements.

The Monsec stations

Connected to Network

Using a UHF radio connection, the station receives the data measured by the sensors and transmits them to the cloud server as it receives them.

Once in the cloud, this data will be represented graphically using the Monsec App.

The station is connected to the network through a power source.

Battery

The sensors transmit the data to the station by UHF radio connection and these are sent to the cloud as the station receives them.

In this way, you can see the information in real time graphically in the Monsec App.

The station is powered by a battery and does not need to be connected to a power source.

Solar

The station receives the data measured by the sensors through a UHF radio connection.

As they arrive, they are transmitted to the cloud where they will be processed and visualized graphically in the Monsec App.

The station is powered by a battery that is charged by a photovoltaic panel

MONSEC® uses advanced sensors and intelligent algorithms developed entirely by the Witeklab team of engineers together with Smart Engineering, a spin off of the Polytechnic University of Catalonia (UPC).

Visit the Monsec® website for more information.